Quality Management: Ensuring LumiGems Excellence

Ahmed establishes how quality will be defined, measured, and assured for the LumiGems project and its smart jewelry product.

Ahmed works with stakeholders to define the quality standards and acceptance criteria for LumiGems. What does 'high quality' mean for the product and project processes?

Ahmed identifies the tools and techniques that will be used for Quality Assurance (preventing defects) and Quality Control (identifying defects), such as testing methodologies, checklists, or statistical process control for LumiGems.

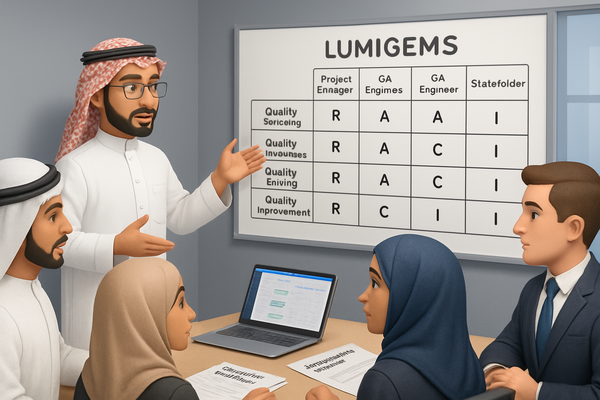

Ahmed clarifies who is responsible for various quality activities. This includes defining roles for quality inspections, testing, and approving deliverables for LumiGems.

Ahmed plans how the LumiGems project will incorporate lessons learned and continuously improve its processes and product quality. This might involve regular reviews or feedback loops.

Ahmed consolidates all quality-related decisions into the formal Quality Management Plan. This document outlines the project's quality policies, objectives, procedures, and responsibilities for LumiGems.